As part of Saudi Aramco’s wider adoption of using non-metallic products in their projects, the Qurayyah Sea Water Injection Department has implemented the first-ever use of fiberglass reinforcement bars inside the plant.

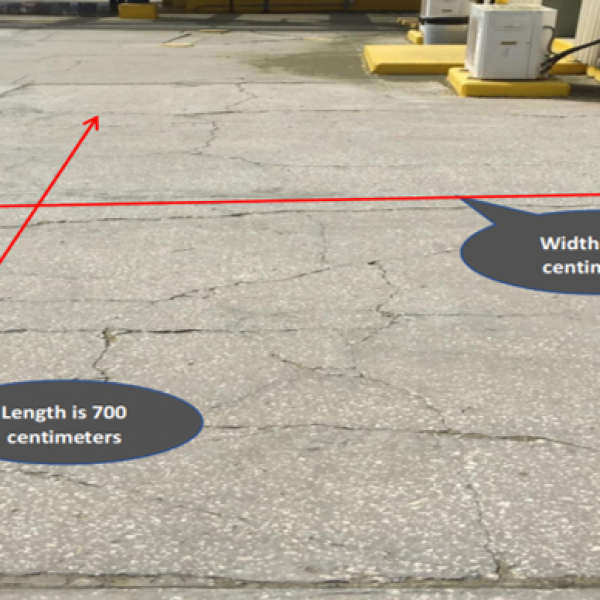

The Seawater Injection Department (QSWP) experiences a high rate of deterioration and damage to the concrete structures.

What is seawater injection?

Seawater injection is a critical part of managing oilfields to keep them in optimal condition and improve oil recovery. Injected seawater replaces the oil that is extracted for the reservoir to offset the pressure decrease caused by oil production. Sea water from the Arabian Gulf is used instead of water to preserve the nation's natural water resources.

Fibreglass Reinforcement Bar: the Foundation to Eliminate Corrosion Risk

The Aramco Qurayyah Sea Water Plant (QSWP) was identified as an area where the pilot project would take place. It is a highly corrosive environment with a never-ending cycle of maintenance and repair due to its close proximity to the Arabian Gulf water body. The project marks the beginning of the use of GFRP rebar inside an Aramco oil plant, illustrating the importance of non-metallic products and their advantages over other alternatives.

No-Corrosion Fibreglass Rebar Ideal Solution

The QSWP is the largest seawater plant in the world and is located on the shore of the Arabian Gulf. The region is characterized by high temperatures, high humidity, seasonal variations in temperature, high salinity, high chloride presence, and sabkha (salt-laden) soil conditions which all lead to early corrosion and concrete spalling.

The QSWP experiences a high rate of deterioration and is making improvements throughout the plant. GFRP reinforcement was investigated and proved to be the superior material in this aggressive environment. Mateenbar™ will provide financial savings for the plant through a reduction in maintenance requirements and improvement in the asset lifecycle.

Aramco's Non-metallic Initiative to Reduce Carbon Emissions

Utilizing Mateenbar™ in this project is a significant stage of Aramco’s non-metallic initiative. The pilot project is the first step in building efficiency, resilience, and sustainability in oil infrastructure by using non-metallic rebar.