Like many cities worldwide, Paris is experiencing rapid growth and planning for the future.

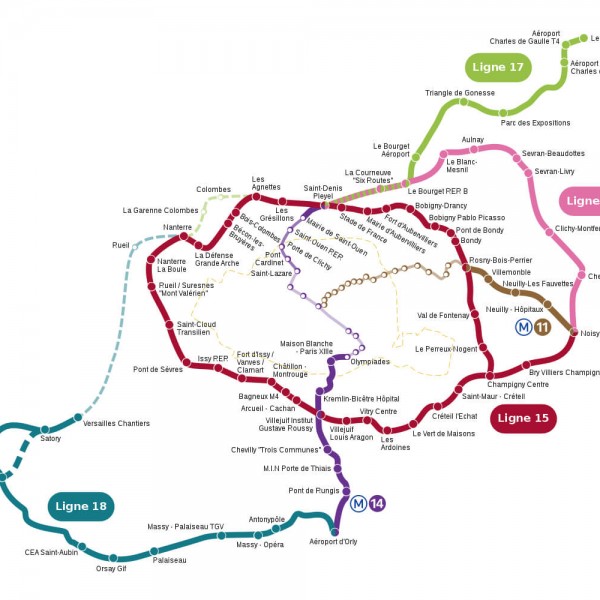

The Grand Paris Express is one of the largest transport project in Europe. 200 kilometres (120 miles) of new track and 68 new stations are to be added, serving a projected 2 million passengers a day.

We supplied Mateenbar™ to two different contractors for the same line in different locations. A 7km tunnel with 14m boring diameter at 70m below ground was needed, with one station needing 1.8 m as thickness. A variety of diameters were used:

- Mateenbar™ in varied diameters: 25/32/38 mm

- Mateenbar™ bends in diameters: 14/20/25mm

Designs were developed with Mateenbar™, using the ACI440 Design standards. D-walls were constructed with Mateenbar™ for easy cutting by the tunnel boring machine leading to improved productivity without costly delays.

The benefits of using Mateenbar™ ‘softeyes’ in tunneling:

- Sustituting steel rebar for GFRP (glass fibre-reinforced polymer) rebar means there is no need to remove reinforcement prior to boring – this practice is slow, cost valuable production time and is a dangerous practice for workers.

- There is no risk of damage to the tunnel boring machine (TBM) when cutting through GFRP rebar.

- It’s quick and efficient to cut through, accelerating the construction schedule.

- GFRP rebar is 4x lighter than steel. This makes it quicker to install and easier to handle for workers; especially important in confined spaces where machinery can’t be used and there is more reliance on manpower.