Awarded by the Dubai Municipality, the purpose of this project is to collect and transfer groundwater and stormwater runoff from the wider Dubai World Central area.

Dubai’s growing urbanization and extreme weather is prone to flooding and high level groundwater. A short rainfall often leads to flooding affecting many sites including the Al Maktoum International Airport and Expolink 2020 areas.

The use of Mateenbar™ allowed for fast, efficient progress when using the tunnel boring machine (TBM), with no delays through breakage.

Flooding in Dubai is often seasonal and leads to airport operational delays, traffic delays, business disruption and damage to buildings. The stormwater tunnel project is vital infrastructure to reduce flood risk and the ongoing costs to the economy.

Maintenance-free tunnel within a corrosive environment

A challenge presented by the client was for the tunnel to be maintenance-free with a 100-year service. The durability of the tunnel especially in a project of this size was paramount. During its use, the inside of the tunnel will be exposed to stormwater containing very abrasive sand, grinding the concrete from the inside – while the outside is exposed to chlorides and sulphates, leading to concrete deterioration. Mateenbar™ provides a corrosion-free, durable and easy to cut material which will withstand these conditions. With a design life of 100 years it meets the requirements set by the Dubai Municipality.

The numbers

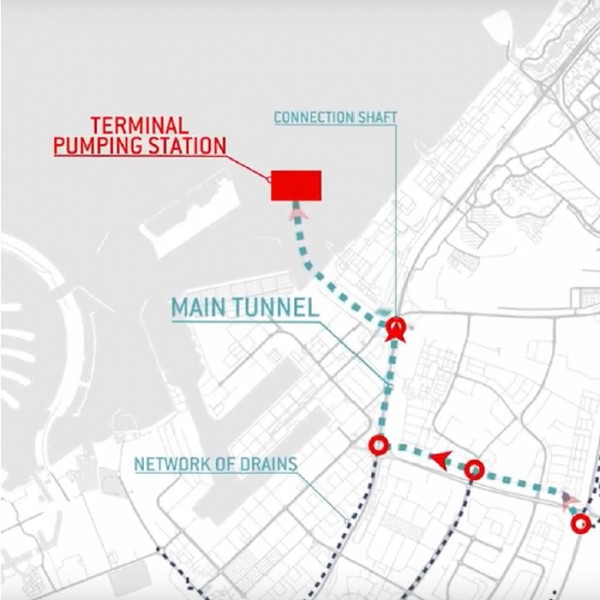

Dubai’s drainage tunnel consists of 5 key elements:

- Drainage network

- Holding pond

- Tunnel

- Pumping station

- Sea outfall.

The tunnel is 10km long and between 30m and 45m deep. The tunnel has 4 deep shafts which are 14-20m in diameter and 60m deep. The tunnel will be able to drain nearly 40% of the entire urban area of Dubai. The system is designed to manage 6.5m3 liters of water (the equivalent to 2,600 swimming pools).

Having a deep tunnel system means gravity does most of the work, requiring only one pumping station making it energy efficient and easy to operate.

Phase 1

Mateenbar™ was used to maintain the overcuts. This allowed the TBMs to drill quickly and without breakage or costly delays. Mateenbar™ bends were used as GFRP concrete spacers on the sides of the primary panels.